Ras Al Khaimah Port Extension, UAE

ESC has been one of the integral suppliers of the development of Ras Al Khaimah port, one of the main industrial gateways to the UAE. ESC supplied over 3,000 tons of sheet piles, H piles with connectors, tie rods and over the duration of the development. ESC's success can be attributed to its unique sheet pile design, local and international production capabilities, competitive pricing and great customer service. ESC's engineers completed full design verification calculations to British Standards which was fully accepted by the owner's consultant.

These projects have covered a timeline of 4 years ranging from 2005 to the end of 2008. All projects were carried out with the same contractor Athena SA.

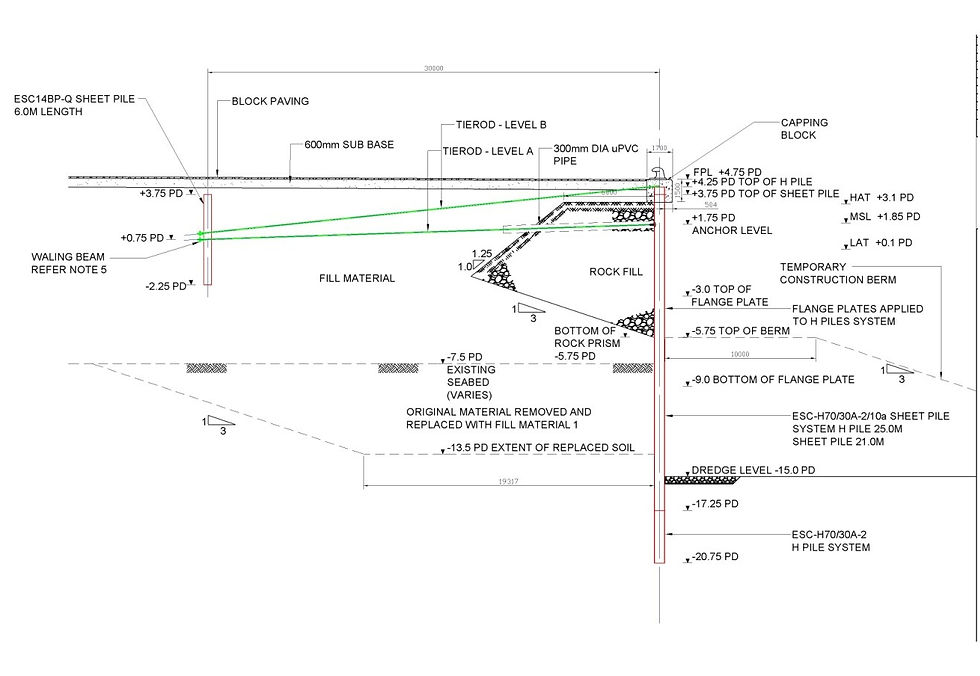

The Ras Al Khaimah Port development is located in Ras Al Khaimah, UAE. An existing port is to be extended by reclaiming land behind a permanent sheet pile wall. The design proposed is a main sheet pile wall tied to an anchoring wall of smaller sheet piles.

ESC proposed to use ESC cold formed fabricated sheet piles for the Main Wall and the Anchor Wall. All parameters were supplied by the client in terms of required capacity.

ESC covered the following scope:

-

Sheet pile requirements and Specification

-

Corrosion design

-

Calculation of sheet pile modulus

-

Connection detail of sheet pile and tieback system

Designs undertaken in all of these projects were in conformance with the relevant British Standards.

The sheet pile proposed for the Main Wall was a custom designed pile specifically suited to this project. The sheet pile was built in a modular style which allows the thickness of the plate to be varied to accommodate different stress levels and corrosion zones.

Full calculations of the derivation of section modulus for the ESC46A (6059) custom pile, and the ESC18A standard pile were supplied to the Client and their Engineers. All calculations were performed in accordance with the guidelines set out in BS 5950 Part 5. Steel piles were manufactured and delivered in accordance with the requirements stated in the BS EN 10249 Parts 1 and 2.

Steel specifications follow those stated in BS EN 10025:1993. All piles contained welded elements. The welding procedure was designed and approved by accredited certification bodies (Lloyds) to ensure complete strength transfer across the welded joint.

Coating Requirements (Phase IA and others)

The specified coating for the sheet piles was for sand blasting followed by 50m of primer and then 400m of coal tar epoxy paint. The coating was applied to the entire front surface and two metres of the back surface of the Main Wall piles only.

ESC will be used a product called JotaCoat 550 for all painting works. ESC work closely with the paint manufacturer and have developed a painting specification that is designed to suit high corrosion environments.

Corrosion Design (Phase IA and others)

The specification for the corrosion design is that the sheet pile must have a design moment capacity of 616 kNm/m after a thirty year period. Coating was not to be considered in this calculation.

Corrosion rates varied along the length of the pile depending on the corrosion zones. Likewise, moments along the length of the pile will vary with the maximum required moment occurring approximately halfway between the anchor point and the dredged level.

The objective of the corrosion design was therefore to ensure that the moment capacity in this zone is at least 616kNm/m after thirty years.

ESC carried out the alternative design calculations on behalf of the Contractor and submitted them for approval to the RAK Government and their Consultant. All relevant drawings and engineering detailing were provided by ESC for all projects. Once approval was received the manufacturing was carried out in the ESC factory for delivery to the site.

Corrosion rates as stated in BS 6349 Maritime Structures Part 1: Code of practice for general criteria ( Table 25) have been adopted.

As always, ESC personnel were on site to assist the contractor during the beginning of the installation process. Several recommendations were made regarding piling guides and handling processes. ESC provided efficient Dawson Lifting Shackles that helped increase the productivity of the installation, while ensuring maximum safety during the process.

ESC's scope of products

-

ESC 46A Sheet Pile S355JOC Grade x 16.5m length (2414 tons)

-

ESC18A Sheet Pile S275JR Gradex 3m length for the anchor wall (283 tons)

-

ESC Pile Shoes (451 units)

-

ESC H60/30B-2 King H Piles (136 tons)

-

Tie Rods, Walings and Brackets (113 tons)

Soil Profile

The existing seabed was between approximately -2.0 EL to +1.0 EL in the vicinity of the proposed wall. Subsequent filling activity has reclaimed the area to approximately +3.0 EL. Fill material is dense to very dense sandy gravel with cobbles and boulders.

The original seabed is a layer of medium dense to very dense silty sand, overlying a medium dense to very dense silty gravel layer with sandstone bands up to 8.0m thick.

Below the gravel layer are pockets of medium dense to dense sands, overlying a very dense sand layer with sandstone bands at approximately -13.0EL.

The tie rods for Phase IA-Extension were supplied by Dextra Manufacturing under the guidance and design of ESC. The rods supplied were M60mm of steel grade 700 in lengths of up to 24.6 metres. Tie rods were wrapped in Denso tape prior to installation.

Installation Details

Installation was done by pitching the sheet piles in a piling frame and driving to refusal with an ICE 815 vibro hammer. Piles were then driven to the final required level using an IHC S90 hydraulic hammer, together with a pile helmet.

Project Photos